Description

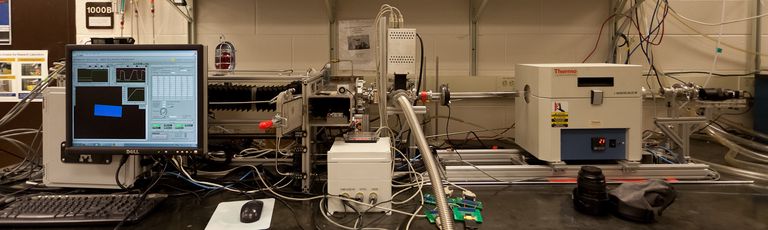

This was a project as part of ME 552 at University of Michigan. One of the project team members (Ryan Oliver) was a member of the Mechanosynthesis Group and had an idea for an automated system for growing carbon nanotubes.

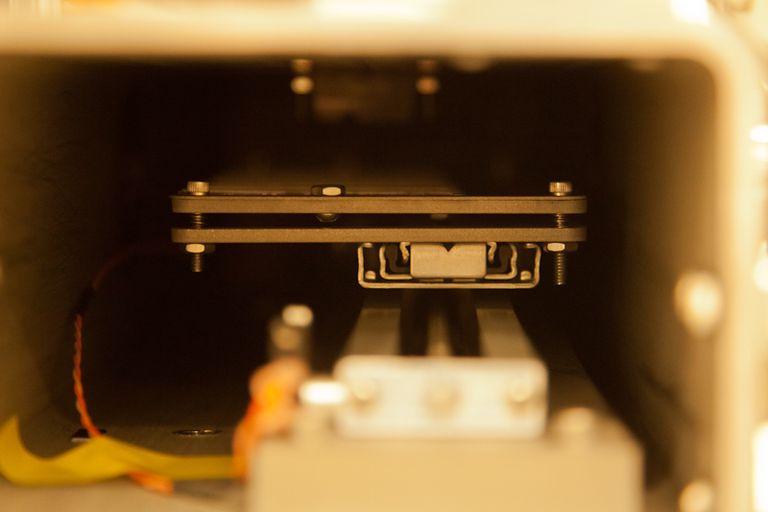

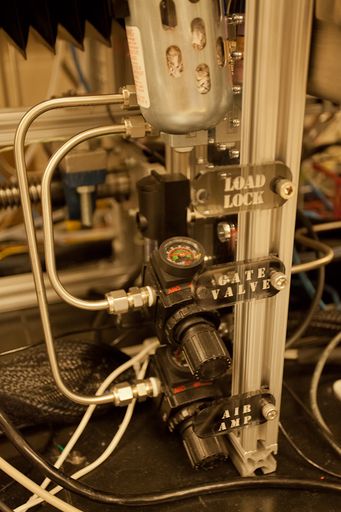

The goal of the project was to develop a system that could run experiments unattended for long periods of time and carefully control the heating, cooling, and growth phases per the researcher’s recipes. We designed and machined a number of mechanical components and the mechanisms for moving the samples throughout the process.

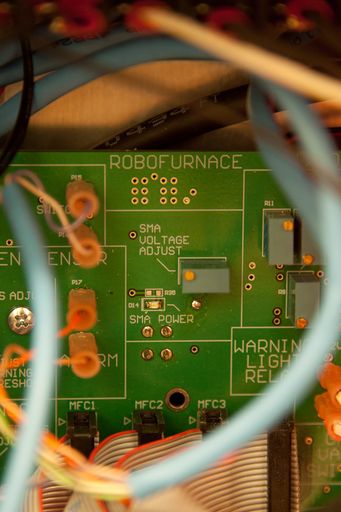

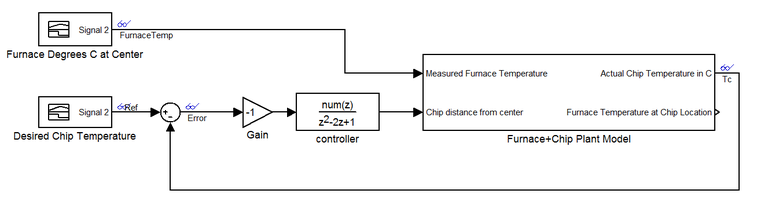

As part of the team, I worked on the electrical and controls components. I made a custom PCB that interfaced with a National Instruments DAQ so that the system could be computer controlled by LabView. As part of the system, we needed to be able to carefully control the rate at which the sample cooled from nearly 800°C once the growth was complete. Since the tube furnace could not cool fast enough accomplish this, we built a motion platform for the tube furnace to move it away from the sample. We measured the temperature profile of the furnace and I used MATLAB/Simulink to develop a second order feedback controller based on the furnace model and a radiative cooling model of the sample. The controller was then applied to the real system through the LabView controller. The cooling process can be seen starting at approximately 20s in the above video.

The project was published in “Robofurnace: A semi-automated laboratory CVD system for high-throughput nanomaterial synthesis and process discovery” in Review of Scientific Instruments in November 2013.