Description

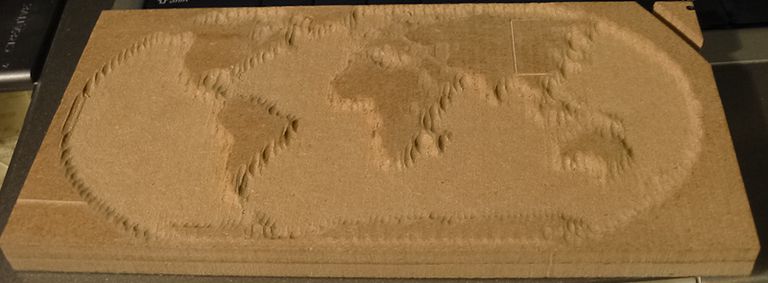

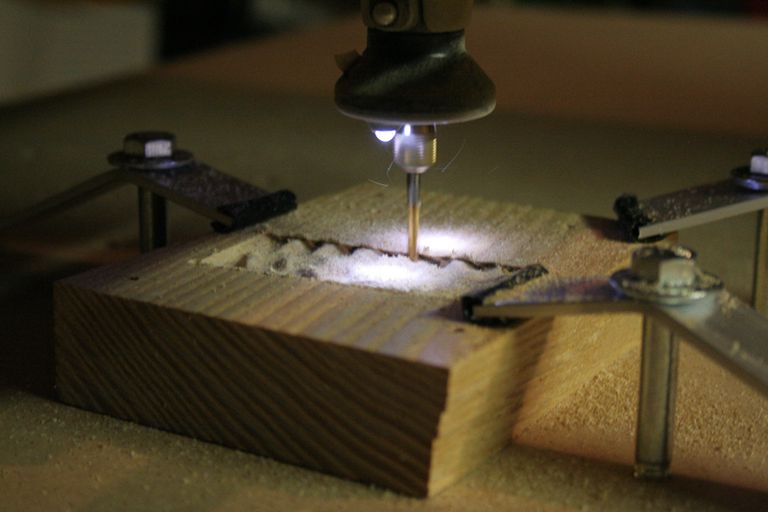

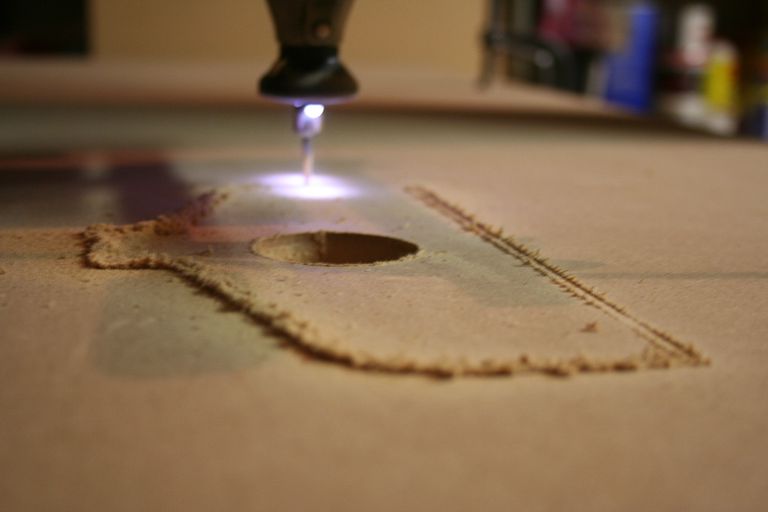

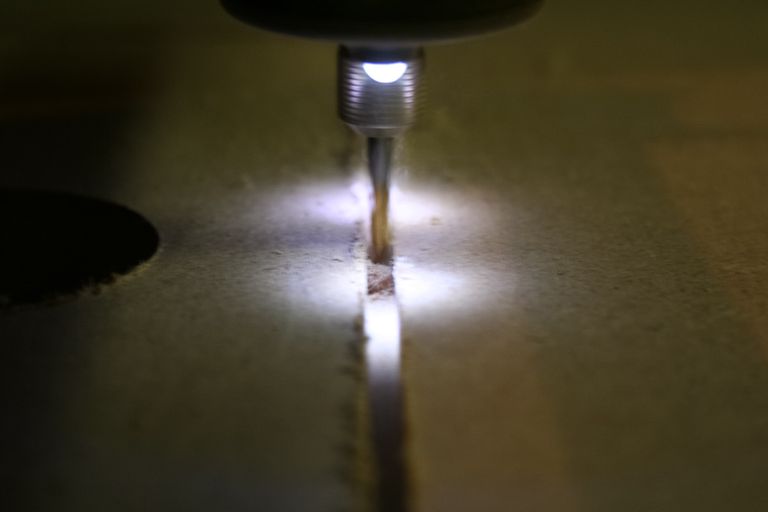

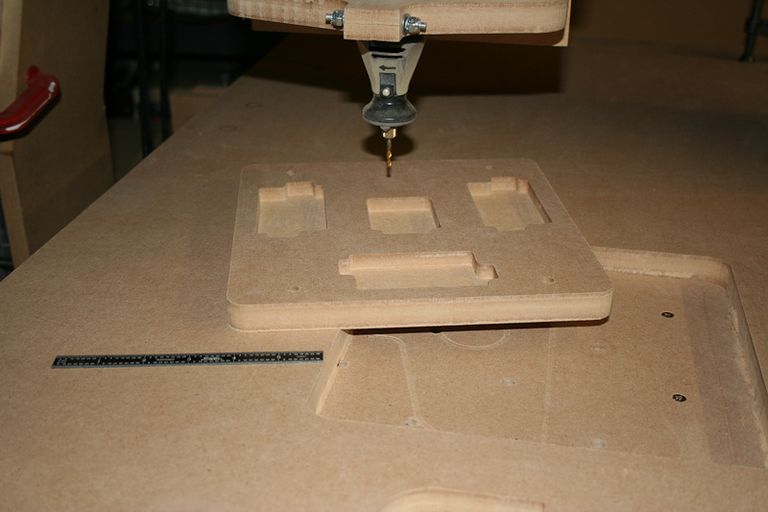

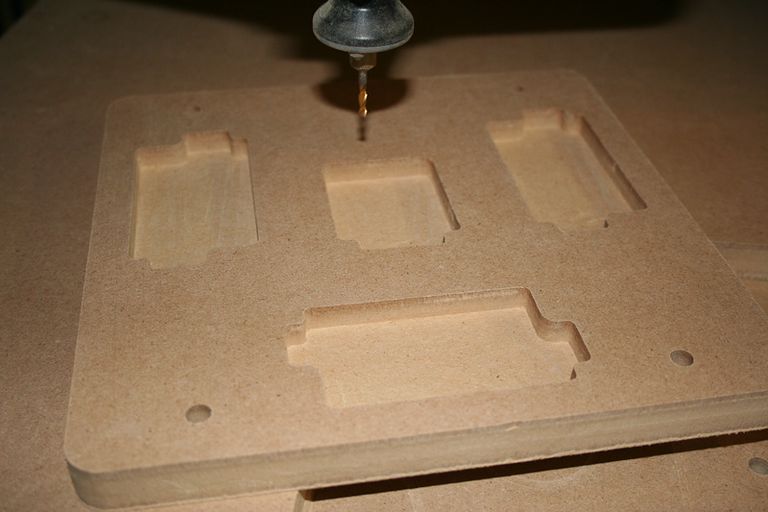

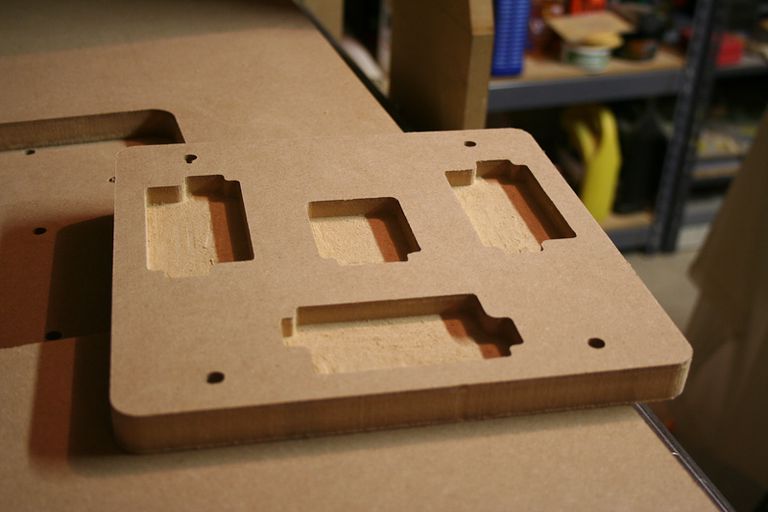

Custom gantry-style 3-axis CNC router built on a student-sized budget over a summer. The axes were driven by stepper motors with custom-made drivers. The majority of the structure was built with 3/4” MDF and standard lumber. I used low-cost skate bearings riding on standard gas pipes and ACME threads with dual nuts to reduce backlash for the linear motion. Since the majority of the parts were made by hand I built a lot of alignment adjustability into the motion components so I could align them for smooth motion. As portions of the machine were completed I was able to use them to fabricate more parts.

EMC2 was used for controlling the machine running on a spare PC with pulse outputs for the stepper motors.

G-code programs were created by hand, with a simple MATLAB script to generate G-code based on 3D functions, or with Inkscape and DXF to G-code conversion utilities.